TEMPORARY PROPPING

'One-Stop' Shop, from Design to Delivery

WHAT WE OFFER

We regularly design, supply and install temporary propping schemes for a range of major projects across the UK. We focus on close collaboration with our clients and partners to ensure a safe and successful temporary propping project, right from initial engagement and scoping through to design and project delivery.

Here's a snapshot of how we work with major contractors to collaborate and deliver propping projects. Find out more about our pre-construction and engineering design services here.

01/ PLANNING & CONSULTANCY

Talk to us early on... We love getting involved before tender stage, to help come up with ideas for a temporary works scheme and support with scheduling ideas. That said, we’re just as happy to look at how we can improve a previously proposed scheme.

02/ TEMPORARY WORKS SERVICE

We collaborate with our clients and their partners from the initial design phase right the way through to a project’s completion. Our in-house engineering team analyse the feasibility of temporary works schemes and provide value engineered solutions to reduce costs and programme duration or improve site logistics.

Here’s some of our capabilities:

- In-house design.

- Structured, sequential, temporary propping schemes.

- Tower crane grillage design.

- Temporary gantry & loading dock.

- Bespoke temporary steelwork.

- Plunge column & bearing pile design.

- Capping beam & pile wall design checks.

- Cat 3 checking of third party temporary works designs.

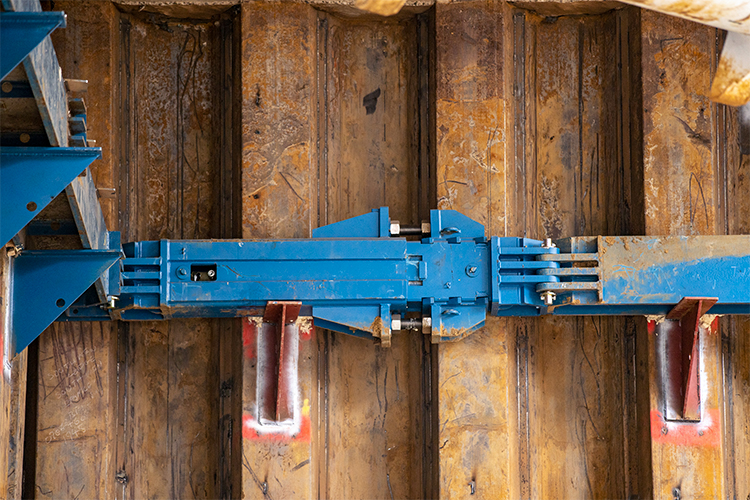

03/ THE SYSTEM

We supply a simple to assemble, modular system, primarily based on three sections sizes that provides a span range from 1.23 to 35 metres, at a loading force of 2500kN.

Our system includes:

- Range of strut sizes up to 1000mm diameter.

- Waling Beam – single and double variations.

- Hydraulic Waling Beam.

- Waling Beam Gallows Brackets.

- Jack, Hydraulic Jack, Cradle, & various connections.

04/ STATE OF THE ART TECHNOLOGY

We strive to provide the best service to our customers, which is why we invest in state-of-the-art technology like the Remote Load Monitoring System that allows the site team and off-site structural engineers to view live, real-time readings of prop loadings.

05/ PROJECT DELIVERY

Scheduling

Our operations team will work with your logistics team to create a transport and install schedule which works around your site limitations and other deliveries.

Installation & Supervision

Our engineers can come to site to train your site team how to install and pressurise the system, or we can provide full installation services.

Checks

We are happy to attend site with 3rd party engineers to carry out checks and provide ongoing support.

Ongoing Support

We will have regular site meetings to ensure you have the support you need. In addition, your engineers have direct access to the design engineers that worked on your scheme, by email, phone, or video call.

06/ NATIONWIDE TRANSPORT

Conquip own a fleet of transport vehicles, from 3.5 tonne vans to 44 tonne articulated lorries, ensuring we can provide our customers with maximum convenience and reliable delivery times.

- In-house, cost-effective transport service.

- FORS Gold licensed operator and a CLOCS Champion.

- Large deliveries, short lead times.

- Reliable, on-time deliveries.

RECENT PROJECTS

LET'S TALK

Tell us more about your project & challenges and one of our engineers will be more than happy to get in touch to discuss your options.