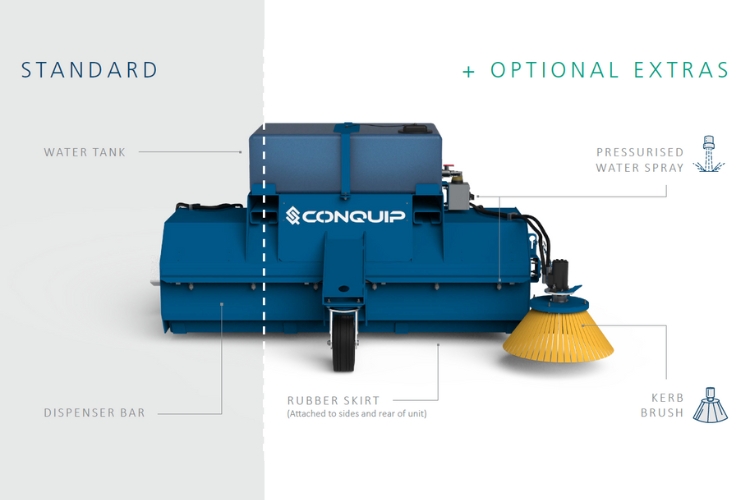

THE BASICS

01 BEFORE YOU START

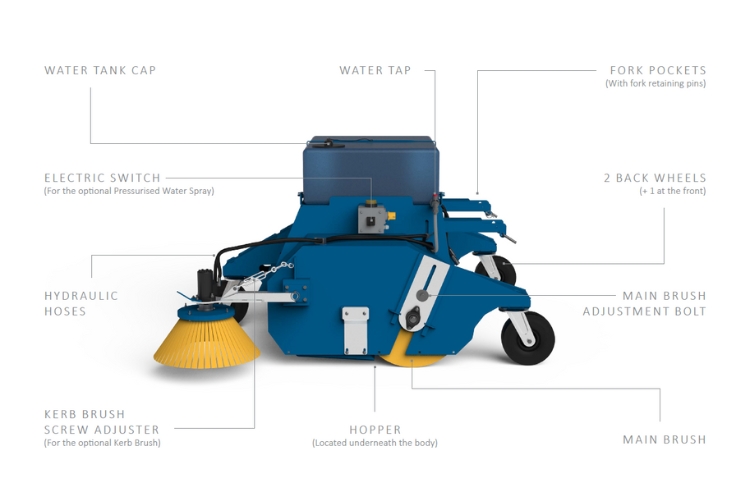

01/ If using the Pressurised Water Spray optional extra, charge the battery with a 110v lead.

02/ Fill the water tank with water (ensure tap is OFF).

03/ Check the bearings on the wheels.

04/ Check there are no hydraulic leaks.

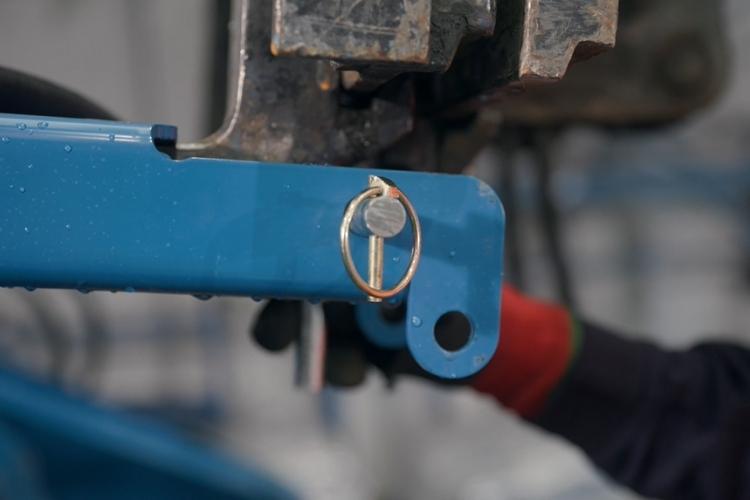

05/ If using the Kerb Brush optional extra, ensure the adjustment chain is in its bracket & the linch pin is secure.

02 HOW TO USE THE POWERBRUSH

03 AFTER-USE CHECKS

01/ Stop the machine and turn the engine OFF.

02/ Release the pressure in the auxiliary line.

03/ If using the Pressurised Water Spray, turn the electric switch Off.

04/ Turn the water tap OFF.

05/ Disconnect the hydraulic pipes. Caution: these will be hot.

06/ Remove fork retaining pins and place them into the storage position. Retract forks from the fork pockets.

07/ Lubricate the grease points (2 points on each wheel, 1 point on the main brush bearing): Using a grease gun, place the nozzle over each grease nipple and apply 3 pumps of lubricant.

08/ If using the Pressurised Water Spray, recharge the battery.

09/ In freezing conditions, remove the hose & drain the water tank.

TROUBLESHOOTING

MISUSE OF THE POWERBRUSH CAN RESULT IN DAMAGE TO THE UNIT.

BEST PRACTICE ADVICE

TROUBLESHOOTING

This section covers some common and easy-to-fix issues, which can be identified by the operator.

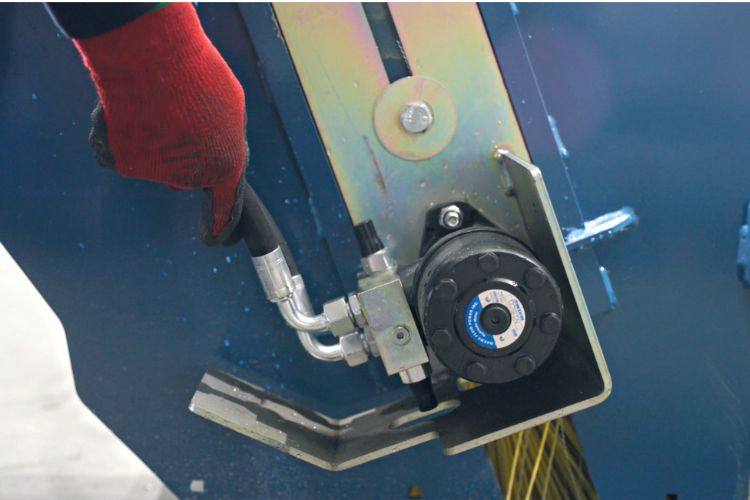

TROUBLE WITH THE HYDRAULIC CONNECTION?

If you are having difficulties connecting the Powerbrush to your machine, it’s possible there is a pressure build-up in

either the machine, or the Powerbrush itself.

TO RESOLVE THIS, TRY THE BELOW STEPS:

01 / CHECK FOR PRESSURE BUILD-UP IN THE MACHINE

Try releasing the machine’s pressure in the auxiliary line. Machine set-ups can differ depending on the model or manufacturer. Refer to your machine’s operator manual for instructions on how to do this.

02 / TRY RECONNECTING THE HYDRAULIC HOSES

With the pressure build-up released, you should be able to reconnect the Powerbrush to your machine. If issues persist, try the next step.

03 / CHECK FOR PRESSURE BUILD-UP IN THE POWERBRUSH

Misuse can lead to a pressure build-up in the hydraulics of the Powerbrush.

Try connecting the two hydraulic hoses of the Powerbrush together. If this is not possible, there is a pressure build-up in the Powerbrush. Please get in touch with us to book an engineer visit to resolve.

INCORRECT COUPLINGS FOR YOUR MACHINE?

At the point of the order, we sent out the correct couplings to match your machine. If you are now using a different machine, you may need new couplings. Contact us.

EXPERIENCING HYDRAULIC LEAKS?

Hydraulic fluid leaks from

the external hoses of the

Powerbrush, or the Kerb

Brush can be caused by loose

hose unions. Try tightening

the unions.

If leaks persist, or in case of

a damaged hose, please get

in touch.

EXPERIENCING WATER LEAKS?

If you are experiencing water leaks from the tank tap, check the tap valve is not clogged with any debris.

To clean the valve, empty the water tank. Unscrew the water tap collar to access the valve. Remove debris, screw the tap collar back on and refill the water tank.

If issues persist, or water leaks are caused by a damaged water tank or hoses, please get in touch.