It’s a topic that causes confusion across the industry. Some might argue this is due to the incorrect use of terminology and others because of their similar functionality, but the question remains: what is the difference between a Spreader Beam and a Lifting Beam?

In this article we aim to provide the answer to this burning question as we look deeper into the science behind how each beam operates, how this provides the best method of determining the differences between them and which is the most efficient beam to choose for a particular lift.

Plus, we pose another burning question: what if there was a beam that could do both? Intrigued? Read on to find out more…

What is a Lifting Beam?

A Lifting Beam has central attachment points on the topside of the beam for attaching to a crane or other lifting apparatus and supports a load via two or more connection points on the base of the beam. If the load predominately puts a bending stress in the beam, it is defined as a Lifting Beam.

What is a Spreader Beam?

A Spreader Beam is a long bar that holds two slings apart, distributing the weight of a load evenly over two or more attachment points. If the load predominately puts a compressive stress in the beam, it is defined as a Spreader Beam.

All cleared up or still just as confused? Let’s investigate further…

The science behind the functionality

If the difference between lifting and spreader beams is defined by the stress applied to the beam from the load, then what is bending stress and what is compressive stress?

Bending stress

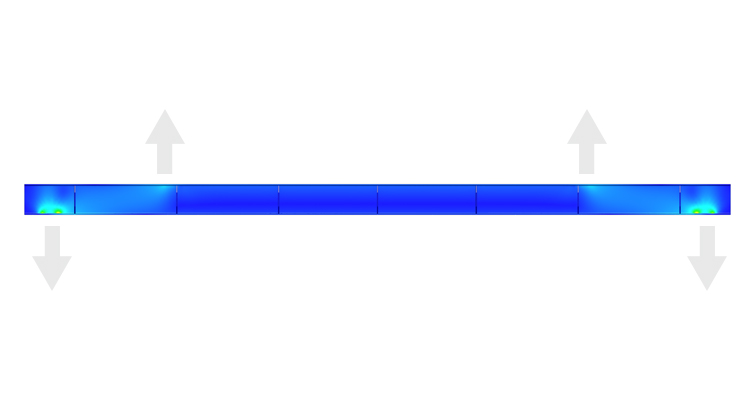

Lifting Beams endure bending stress as the force travels up from the bottom slings, along the beam to the central fixing point(s) and into the crane hook via the top sling as shown in Fig.1.

The lighter-coloured areas are where the stress is greatest. Fig.2 shows the stress applied to the central fixing points.

Fig.1

Fig.2

Compressive Stress

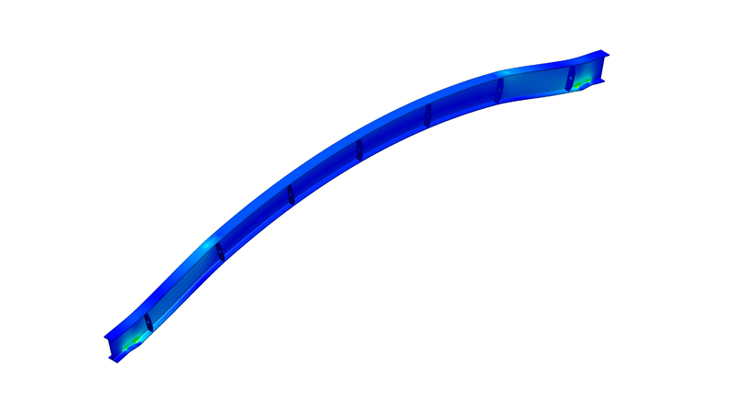

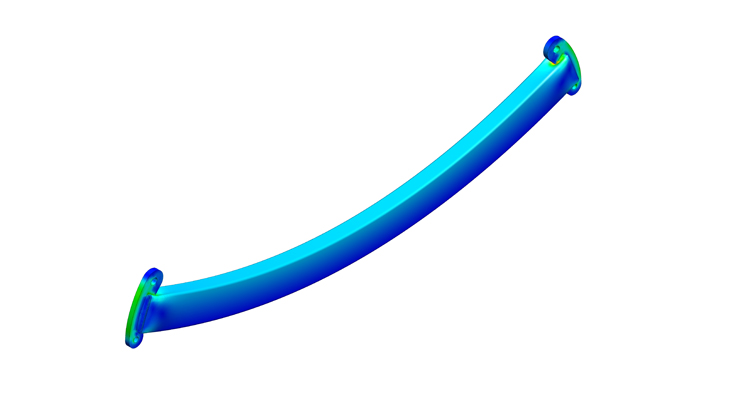

Spreader beams endure compressive stress as the force still travels up from the bottom slings.

However, as soon as it reaches the beam, the force travels up the top slings to the crane hook, eliminating any bending stress on the beam from the load, as illustrated in Fig 3.

Fig. 4 shows how the force spreads across the width of the beam

Fig.3

Fig.4

The advantages of Lifting Beams

- Lifting Beams require less headroom (distance between crane hook & lifting point(s) of beam).

- Multiple lifting points ensure they can be used for different types of loads and applications.

- Durability makes them ideal for transporting loads weak or flexible loads, such as: lengths of rebar.

Disadvantages

- Lifting Beams use more material, are generally heavier and therefore are more expensive to manufacture than Spreader Beams.

- Tag lines may be required for long beams or uneven loads to retain control and reduce the chance of spinning.

The advantages of Spreader Beams

- Very efficient in their use of material, usually smaller and cheaper than Lifting Beams.

- Even weight distribution allows for large & awkward load lifts.

- They stabilise loads, reducing chance of tipping or bending and being crushed or damaged.

- They can be manufactured to allow for incremental adjustment of sling angle for off-centre load adjustments.

Disadvantages

- Spreader beams require more headroom to accommodate for the overhead slings, so they are not ideal for lifts where overhead room is limited.

- Tag lines may be required for long beams or uneven loads to retain control and reduce the chance of spinning.

How do I choose between a Spreader Beam and a Lifting Beam?

When selecting the right beam to use, ask yourself the following questions:

- What am I lifting?

- How am I lifting it?

- What is the size and weight of the load?

- Where is the load being lifted to?

It is important to consider the weight of the object being lifted and where the lifting points are located. Spreader Beams will be more effective for loads that have wide spans.

However, if the length of the load needs to be supported throughout the lift, then it is best to choose a Lifting Beam as Spreader Beams are unable to support loads in the middle.

Finally, if the destination of the lift has limited headroom then a Lifting Beam must be used but it’s worth bearing in mind that even if the load is very light, a wide span will still require a solid Lifting Beam.

...but what if you didn't have to choose?

2 in 1 Solution

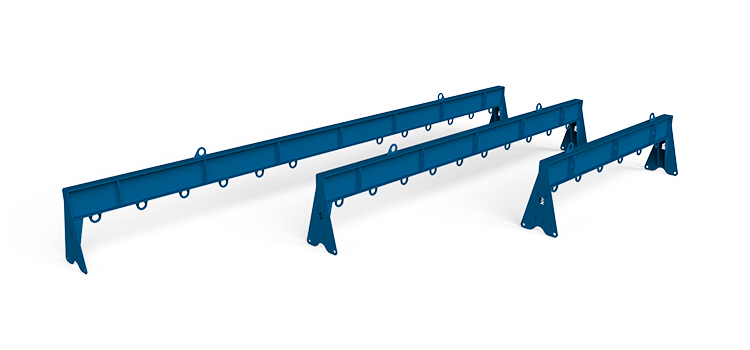

The Adjustable Lifting Beam does both

After talking with customers, we identified a requirement for a solution that could achieve the functionality of both a Spreader Beam and a Lifting Beam, to transport a variety of loads efficiently and safely…introducing, the Adjustable Lifting Beam!

Movable lifting points allow for even weight distribution, including loads where the centre of gravity is not centrally positioned.

With no need to adjust the lifting chains for uneven loads, test lifts are reduced, minimising manual handling.

A large Working Load Limit of 10,000kg makes the Adjustable Lifting Beam ideal for large or awkward lifts, such as modular pod installation.

Main Benefits

- Horizontally-adjustable lifting points ensure uneven loads can be safely lifted.

- Reduced manual handling increases efficiency and safety.

- Its versatility allows it to lift a variety of different loads.

- Multiple lifting points handle loads that require a 4-point lift.

Need a beam for your next project?

We have 3m, 5m and 7m standard Lifting Beams available from stock but we can also manufacture bespoke options such as the adjustable lifting beam.

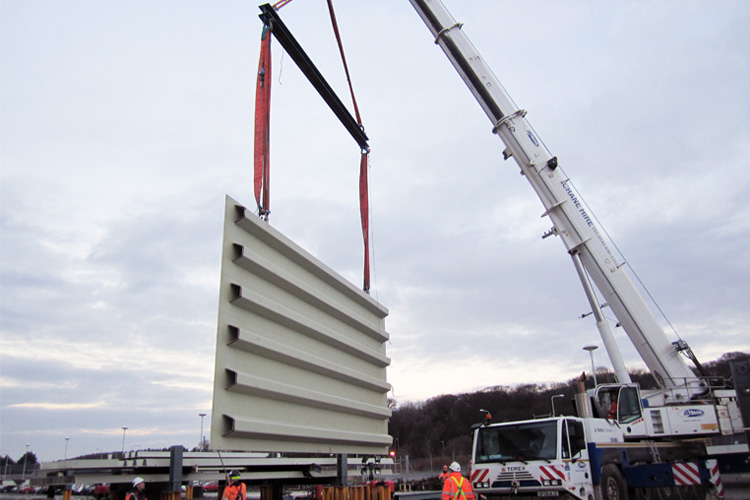

On the Queensferry Crossing project, we manufactured a Lifting Beam with a capacity of 91 tonnes, strong enough to transfer the bridge bottom deck panels. This project demonstrated the range of lifting equipment we offer and our capability to provide solutions to the most demanding applications.

More lifting solutions?

Conquip offer a wide range of standard range lifting equipment, including, Lifting Beams, Goods and Personnel Cages, Grabs, Grips and most recently, the Excavator Lifting Platform.

Plus, our design and steel fabrication capabilities ensure we are well positioned to offer bespoke solutions like the Adjustable Lifting Beam.

Why not get in touch and see how we could support you?