In recent months, there have been several safety incidents involving Concrete Skips.

It’s not a new challenge. There was a fatal incident relating to bale arm misuse in 2014. As a result we worked with leading contractors to develop a Concrete Skip without a bale arm.

Video: How to safely use a bale arm

The Challenge

A few incidents have involved the unsafe or incorrect use of the bale arm, which has caused entrapment or crushing. Some of the safety alerts that have followed, have effectively banned concrete skips from site, because of the unsafe use of the bale arm.

As a manufacturer of Concrete Skips, we wanted to clearly set out the safe use of the most commonly used skip, the Concrete Column Skip. So, in this article we delve into how sites can safely use, maintain, store, and transport Concrete Column Skips with bale arms but also look into some of the alternative solutions that you can use for safely pouring concrete.

What is a bale arm?

A bale arm is essentially a spreader beam to facilitate the balanced lift of a concrete skip. The arm pivots at each side of the skip meaning that the skip gradually lifts off the ground after the skip has been filled with concrete. All traditional concrete skips feature some sort of bale arm as it is the most functional, robust way to lift and lower concrete skips off the ground.

Putting safety first – using your Concrete Column Skip correctly

When the Column Skip is in use, the only time the bale arm should be in the upright position is while the skip is being filled with concrete. During the filling process, the crane hook should remain attached, supporting the weight of the bale arm.

Once filled, use tag lines to guide the skip to its destination to ensure no personnel are close to the load. Operatives should never be stood underneath, or near the skip while it is being lifted.

Download our User Guide below for full operational details. Plus, check out the video below covering exactly how the bale arm should be used to ensure site personnel remain safe at all times.

HOW TO SAFELY USE THE BALE ARM

How to maintain your Concrete Column Skip

The main problem sites face with maintaining concrete equipment is the build-up of dry, hardened concrete after it has been left to ‘set’ or it has not been cleaned out properly after use.

This build-up is tough to remove and requires more extensive cleaning, including physically scraping or chipping away the concrete, sometimes forcing operatives to put their limbs inside the mouth of the skip, lean into it, and in some cases, even climb inside it.

So, what’s the solution?

Firstly, cleaning the skip at the end of every use will eliminate the build-up of dry concrete, ensuring the skip can be sufficiently cleaned using a hose.

Secondly, if there has been a build-up of hardened concrete that requires more rigorous cleaning, lower the bale arm into the resting position, which will guarantee it cannot suddenly fall if the skip moves.

If you do have concrete build-up in your skip that you can't safely clean on-site, our workshop team will be ready to help.

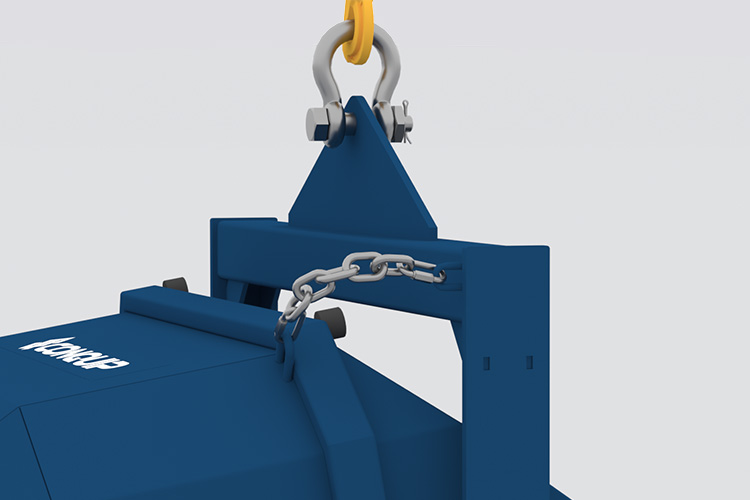

How to attach the safety restraint chain

The only time the safety restraint chain should be attached is for storage or transport. With the bale raised and secured by the safety restraint chain, it reduces the amount space required to store the skip, while preventing the truck becoming a wide load during transport. To attach the safety restraint chain, the bale arm needs to be in the upright position.

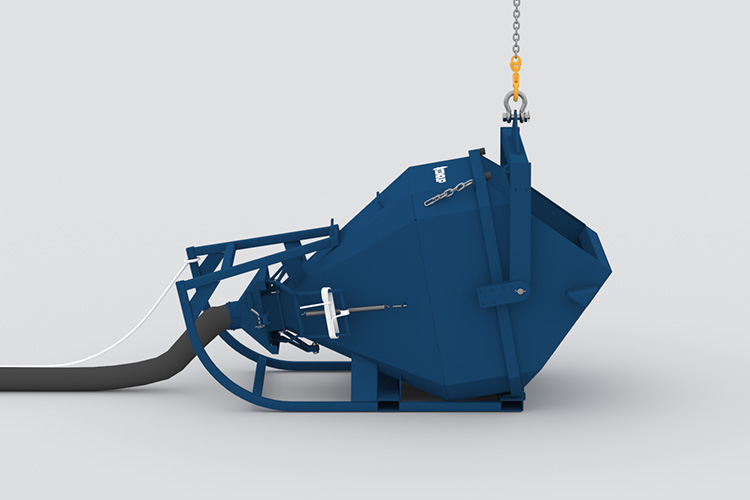

- Lay the skip on its side on a flat surface or level ground.

- With the crane hook still attached, holding the bale arm safely in the upright position, undo the carabiner link on the safety restraint chain, place the link over the lug/eye on the back of the bale arm and fasten it again until it is tight.

- Standing to the side of the skip, move the bale arm back and forth to check it is secure. On the larger skips the bale arm will be too heavy to move by hand so use the crane to check this.

Conquip’s Concrete Column Skips with bale arms have always been manufactured with safety restraint chains to ensure our customers receive these space-saving and cost-saving benefits, whereas other manufacturers either do not feature them or have been retro-fitting them recently.

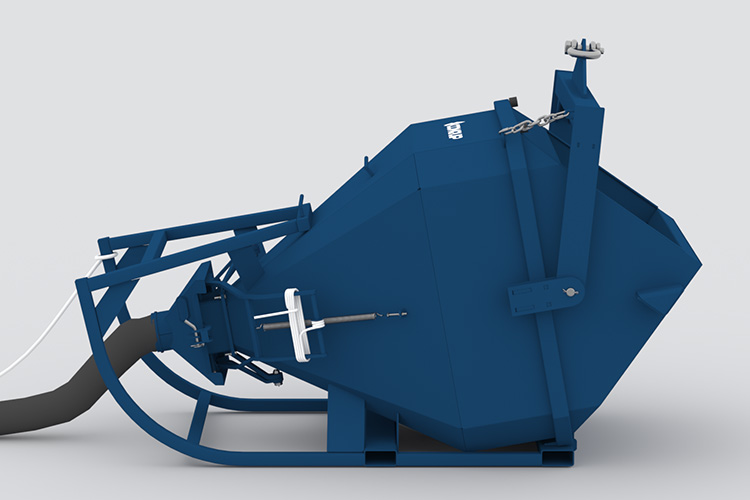

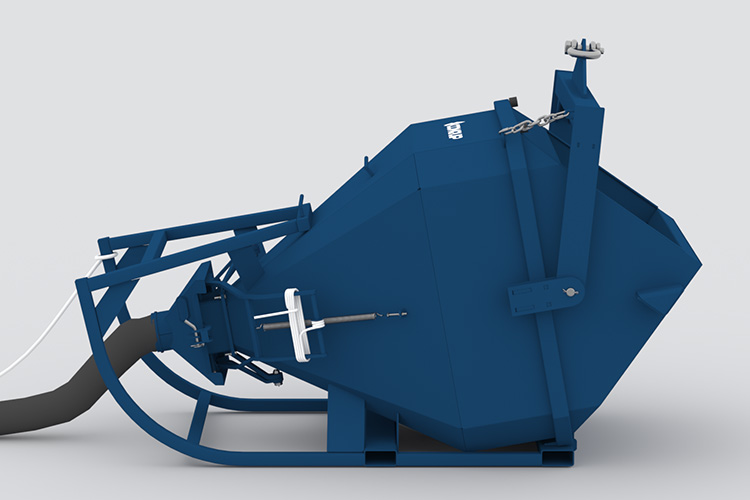

What is the resting position of the bale arm?

The resting position of the bale arm differs depending on whether the skip is sat on a Skip Washing Platform or lying flat on the ground.

When the skip is on a platform, the resting position is when the bale arm is fully lowered,

facing the working platform.

When the skip is placed on the floor, the resting position is when the bale arm has been fully lowered so it sits horizontally with the axis of the skip.

Using in conjunction with a Skip Washing Platform

Using a Skip Washing Platform is the safest and most efficient way to clean your skip:

- Crane-lift the skip into position and lower it onto the platform using taglines to avoid operatives being near or underneath the load.

- Make sure no operatives are stood on the work platform when the skip is being crane-lifted into position.

- As the skip rests on platform, lower the bale arm into the resting position so it is horizontal and facing the work platform.

- An operative can now enter the platform and attach themselves to the harness point.

- Wash down the skip so it is clear of all concrete residue, ready for the next use.

For more information, download the Skip Washing Platform User Guide

No space for a platform on your site?

Are you sure? You may be surprised to hear that the Skip Washing Platform is the same length as the Concrete Column Skip laying on its side with the bale arm in the resting position.

Using without a Skip Washing Platform

- Crane-lift the skip into position using taglines to avoid operatives being near or underneath the load.

- Make sure no operatives are stood near the skip while it is being lifted into position.

- Ensure the ground/surface is level/flat.

- Lower the skip to the ground using the roll frame for a smooth and gentle landing.

- Attach the safety restraint chain and test to ensure it is secure. Alternatively, lower the bale arm into the resting position so it is fully horizontal.

- Do not release the crane hook until the bale arm is secured.

How to safely store & transport your Concrete Column Skip

Storing on a platform

Once the site has finished using the skip for the day, it should be properly cleaned as per the ‘How to maintain’ section above. It can then be stored on the platform with the bale arm in the resting position.

Storing on the ground

If you have more than one skip or need to store the skip on the ground, the skip should be laid flat on its side, on level ground with the bale arm in the resting position. If you do not have any space to store the bale arm in the resting position, it can be stored in the upright position, but the bale arm must be secured with the safety restraint chain.

Preparing for transportation

When transporting the skips to and from site, the bale arm can sit in the upright position to save space on the back of the truck and prevent it becoming a wide load, if the skip is being placed horizontally across the truck bed. The bale arm must have the safety restraint chain attached correctly to ensure the bale arm is secure.

What are the alternatives to Bale Arm Concrete Column Skips?

These recent incidents have led to some contractors removing or banning any skips with bale arms completely from their sites. So, what are the options if you are in this position, or if you are looking for an alternative on your site?

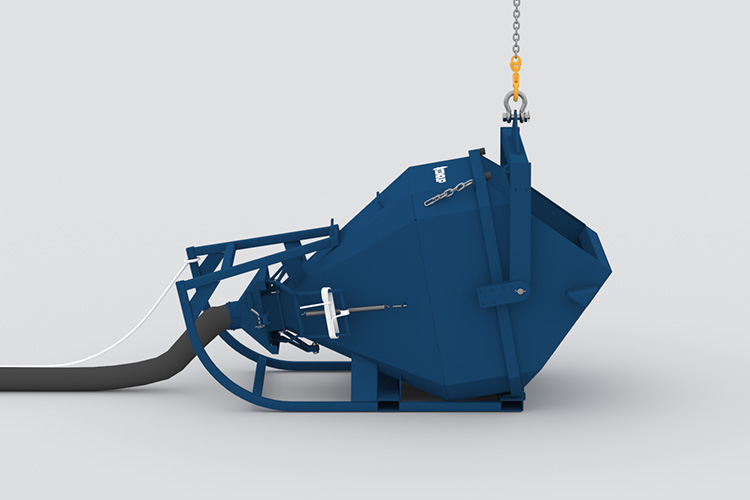

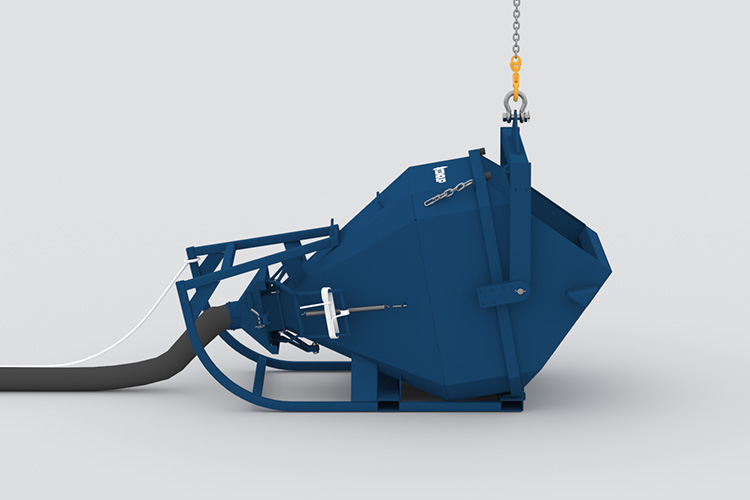

This will commonly be determined by the application, site, and crane availability, but let’s start with the instant alternative – the Concrete Column Skip Without Bale Arm…

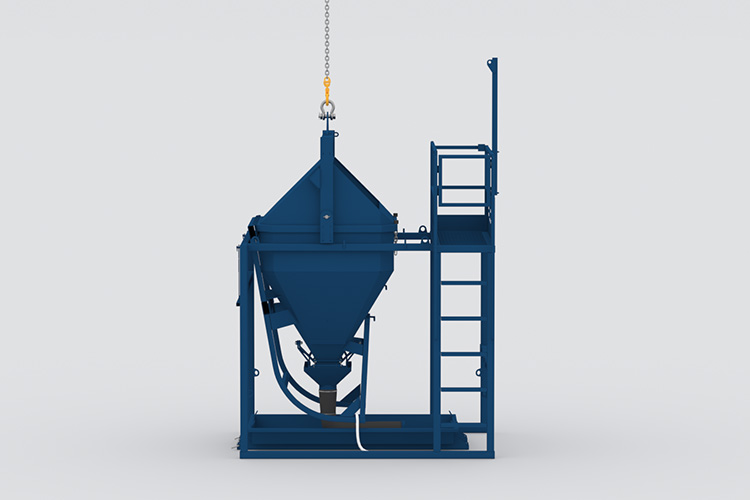

Why we developed a Concrete Column Skip without a bale arm

Back in 2014, following a bale arm incident, Conquip worked with leading contractors to develop the first Concrete Column Skip Without a Bale Arm.

The incident in 2014 happened after an operator climbed into a skip to clean the skip out, while the bale arm was in the upright opposition and not secured with a restraint chain. The bale arm somehow was dislodged and fell on the operator, causing a fatal injury.

What were the initial responses to this version?

“The new 2000 litre Skip that we have on hire from yourselves is much safer than ones I have used/seen previously as it doesn’t have the large swing arm (Bale Arm) that could potentially fall on to somebody.”

Jack Walters, Project Engineer | Keltbray (01 December 2015)

“By simply changing the lifting from a solid bar to lifting eyes you have taken away pinch points and finger trapping points. Also, you don’t have to be worried about how you land the skip to wash it out, which is so much easier. Good job.”

Thomas McDermott | Fayat Piling (21 January 2016)

“Feedback from our concrete foreman he has heard of people getting injuries from the swing bar type and therefore thinks it’s a good idea to change to the 2-leg chain method to eliminate this.”

Mike Hodges, Plant & Logistics Manager | Laing O’Rourke (22 January 2016)

Why are these skips not as common as the bale arm version on construction sites?

The short answer – it takes time to break tradition, especially changing a methodology that has been used across the industry for many years. Unfortunately, sometimes it takes a serious accident to implement action.

However, change can be good…look at the Crane Forks Cage as an example. The traditional method for lifting palletised material around site was Crane Forks with a Safety Restraint Net but following the death of a member of the public after a load fell through the net, the industry reacted to find a better solution.

So, we developed the Crane Forks Cage, a fail-safe method, to prevent accidents like this happening again. See how we changed opinions of major contractors and broke the tradition in our blog.

What are Conquip doing about this?

Following all these incidents, we have been asked by many contractors to remove the bale arms from their purchased Concrete Skips and retrofit them with lifting chains. Our response: we cannot do this.

It’s important for the industry to understand that the Concrete Skips with Bale Arms were not designed to be fitted and lifted with lifting chains, but rather with a robust bale arm which acts as a spreader beam to reduce the point loading. To retrofit them now would put a compressive force through the skip which would reduce the integrity of the skip. To learn more about compressive forces, click here

One of our brand values is to improve safety on construction sites, so if a retrofit delivered a quick improvement, we would be ready to deliver it. However, in this instance, we run the risk of putting a product back into the market that is more unsafe than using a bale arm.

If I am a contractor, what should I do about it?

We would recommend that you immediately use this video: ‘Concrete Column Skip: How to Safely use the Bale Arm’ to educate your lifting and slinging teams and make sure that our User Guide is readily available on any projects where you are currently using a Column Skip. A Column Skip with a bale arm is not inherently unsafe, it is the misuse of the the bale arm that is the issue.

We understand that some main contractors and clients may have issued a statement to prohit the use of a Concrete Column Skip with Bale Arm.

However, if you are working on a project where the main contractor or client have prohibited the use of a Column Skip with a bale arm, please get in contact with us for a demo or rental of a Column Skip without a bale arm.

Any other questions?

If you have any other questions about the safe use of Concrete Skips, including concrete washout or pouring concrete, click on the button below to speak to one of experts.