CANTIDECK

TEMPORARY

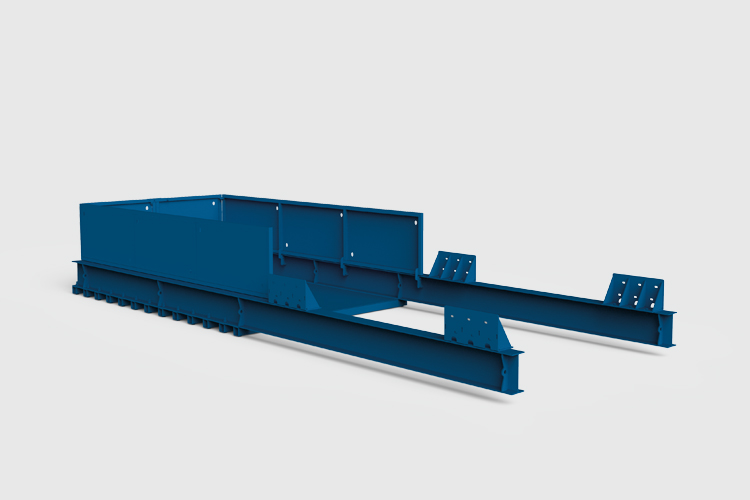

LOADING PLATFORM

Temporary loading platforms that allow materials and equipment to be loaded in and out of buildings and structures.

SAFER WAY OF LOADING

Using CantiDeck eliminates concerns around other common vertical logistics methods:

- Safety of personnel while working at height.

- Inefficient crane movements.

- Costly temporary works and scaffolding systems.

- Ability to move heavy or large loads.

TWO WAYS TO 'DO' CANTIDECK

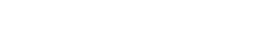

FIXED FLUSH

SMOOTH TRANSITION FROM THE FLOOR TO THE DECK

- Unique single prop design.

- Quick and simple to install & relocate.

- Ideal for places with reduced head room.

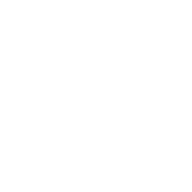

SUPER ROLLER

FULLY RETRACTABLE TO SIT FLUSH WITH BUILDING'S EDGE

- Can be installed in 'stacked' configuration of multiple platforms.

- Allows a reduction of dynamic loadings in high winds.

- Quick and simple to install and relocate.

GET CANTIDECK ON YOUR PROJECT

Our CantiDeck engineers are here to help you find the right approach for your lifting programme. Simply let us know what you need and we will take care of the rest!

WHY CHOOSE CANTIDECK?

Common applications include:

STEEL FRAMES

CONCRETE STRUCTURES

HIGH-RISE

PERSONNEL ACCESS

TUNNELS & SHAFTS

EFFICIENT

The fastest loading platform for relocation and installation. High Working Load Limit capacity to enable loading of a wide variety of materials and equipment.

SAFE

We provide on-site training, provided so that site opeartives can relocate platforms safely, when required on site.

COST-SAVER

Systems such as the CantiCrane can reduce overall project time. Less expensive than complex scaffolding systems.

CONFIGURATIONS

We offer a wide range of different configurations to ensure the CantiDeck loading platform can work in a variety of applications.

Also, there are configurations which increate the safety of the use of the CantiDeck, such as high sides, which provide extra protection for site workers when singing and banking awkward loads.

HIGH SIDES

BOLT DOWN

WALL BRACKETS

RECENT PROJECTS

ALL YOU NEED TO KNOW

Download our handy guide to CantiDeck and get all the answers you need.