Originally the method for cleaning a secant pile wall was time-consuming and largely ineffective. The Excavator Pile Scraper was designed to improve the efficiency of pile wall cleaning and provide major time-savings for this process. After a prototype was developed, find out how the Excavator Pile Scraper faired on its trial below.

An answer to secant pile wall cleaning

Our innovate team noticed how long it was taking basement and civils contractors to scrape down the secant pile walls, before pouring the concrete lining wall. We came up with a solution and trialled it with Getjar Construction (Masterson Holdings) in Kilburn. Watch the video and read the blog to find out more.

So how did we come up with this solution?

During 2018, we were out visiting projects at basement excavation stage. One certain process we noticed was particularly inefficient was the preparation of the secant pile wall before the concrete lining walls could be poured.

One of the tasks that took a long time was the cleaning and scraping of the pile wall. (Both contiguous pile walls and secant pile walls need to be cleaned to prepare for a concrete lining wall.) We saw many methods, but common methods included: using hand-held tools, scraping with the excavator bucket or blasting material using a pressure washer. These methods were time-consuming, labour intensive and costly. If not factored in, the process could end up slowing the project down by weeks. At one project, the contractor began incurring extra charges for using the excavator bucket to scrape the pile wall, as the process was damaging the buckets.

Building the Design Brief

We knew we could improve the efficiency, so we put the issues to our design team and the questions began to fly around the room: Is there a standard diameter thickness for a CFA pile wall? What machines does this solution need to be compatible with? What stage of the project is this? How fast does this process need to be? And so on…

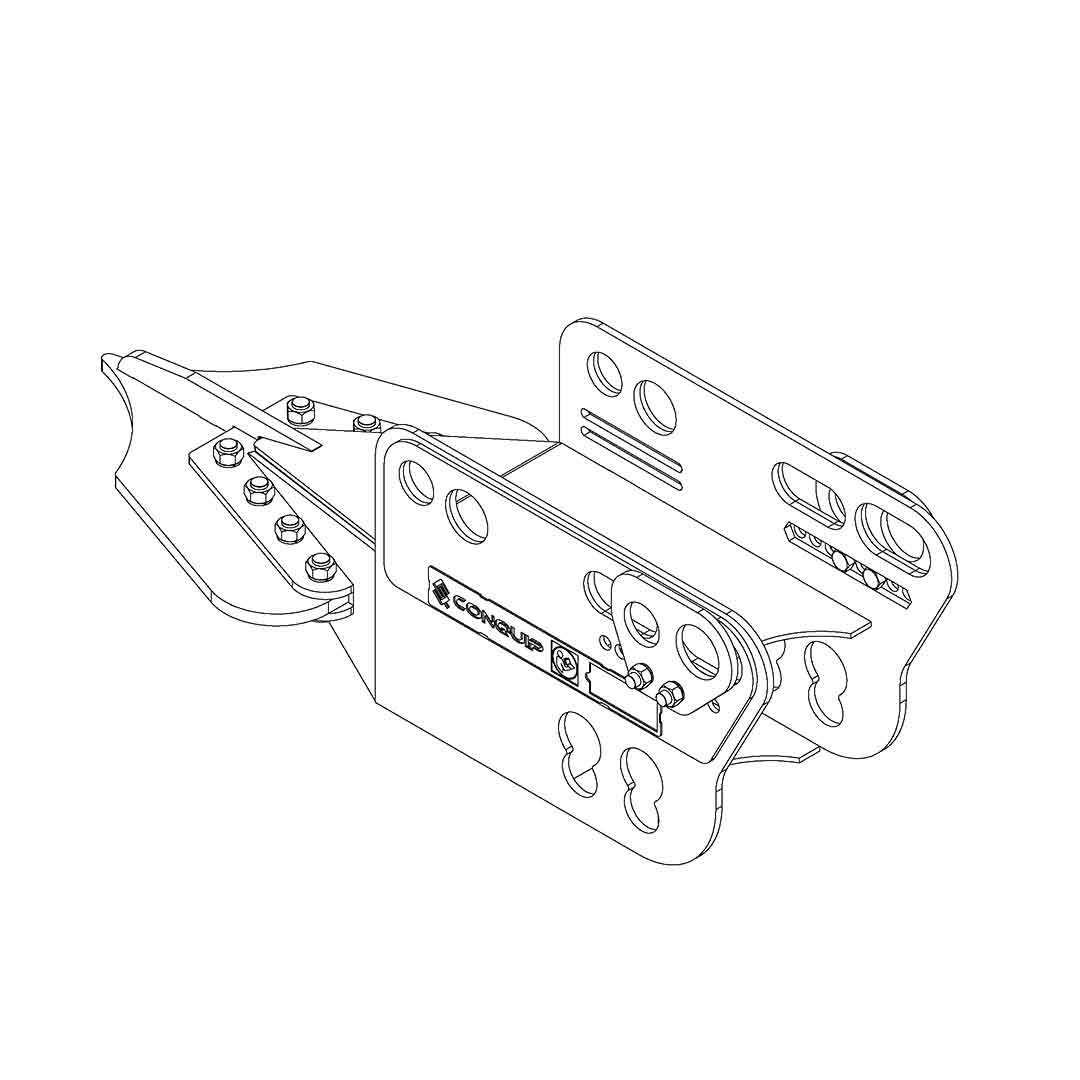

Immediately we had a bullet-proof brief. A simple, scraping solution that would work for a variety of pile wall types and diameters, and could be fitted to a 13-22 tonne capacity excavator. It also needed to be robust so that it didn’t break or wear too quickly.

We came up with a few design concepts, which varied in price and functionality. We compared the designs with our brief and we knew it needed to be simple. So, we tweaked one of the concepts, received positive feedback from a piling contractor and arranged for it to be prototyped.

Putting It to The Test

To really put the solution to the test of a live construction site, we needed to send the Excavator Pile Scraper out on a trial.

Getjar (Masterson Holdings) are carrying out the basement excavation, construction and the reinforced concrete frame construction for the South Kilburn residential development project, currently under construction by Telford Homes. We arranged the trial with Getjar at the excavation stage and attended site to get their feedback.

To find out more about the Excavator Pile Scraper and it’s benefits and specifications, click below.