Forklift Tipping Bins

The tipping bin, a compact forklift bin for transportation of materials and waste on site, is one of the most common pieces of waste management equipment found in nearly every house-building project

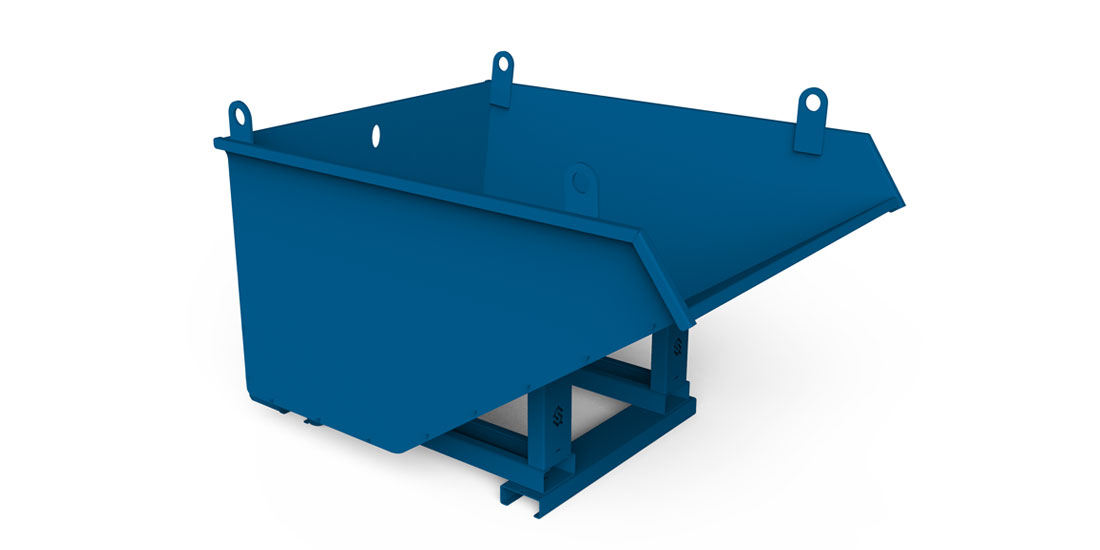

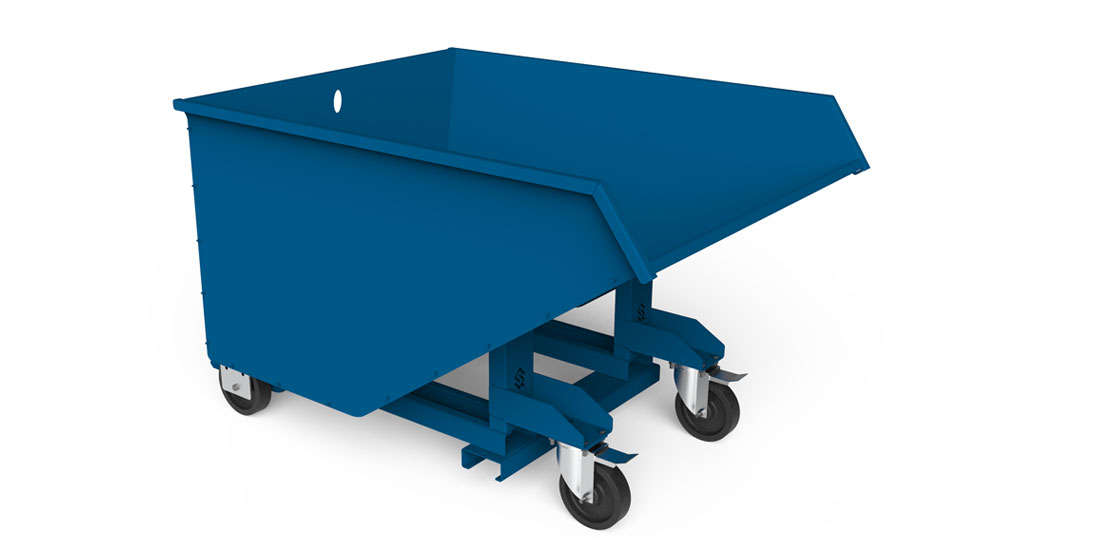

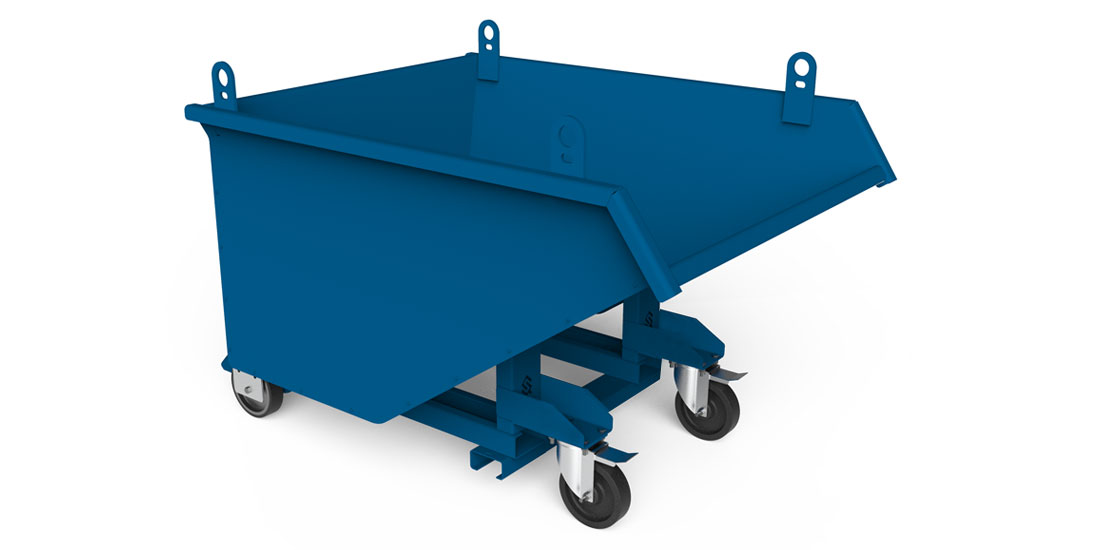

While you may find a variety of design and manufacture options in the market, two of the most common variations of the tipping bin are the auto, or self-tipping bin and standard forklift bin.

How Does a Tipping Bin Work?

A standard tipping bin is mounted on the forks of the forklift and manually attached by a safety chain. The release lever controlled by the driver allows for easy tipping and the return position of the bin.

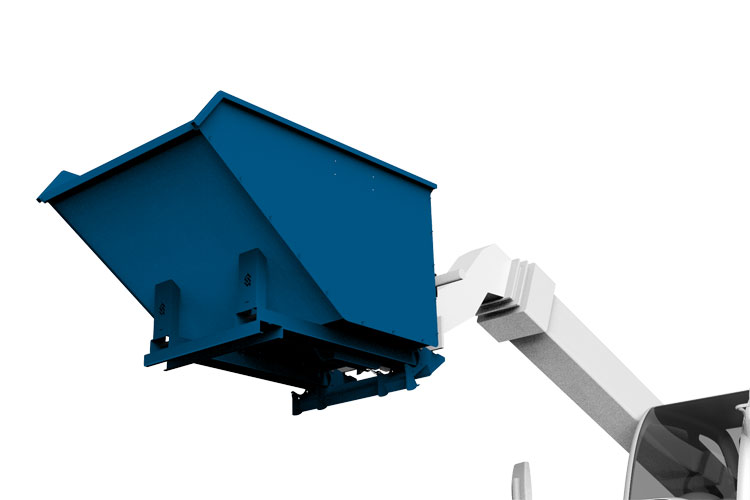

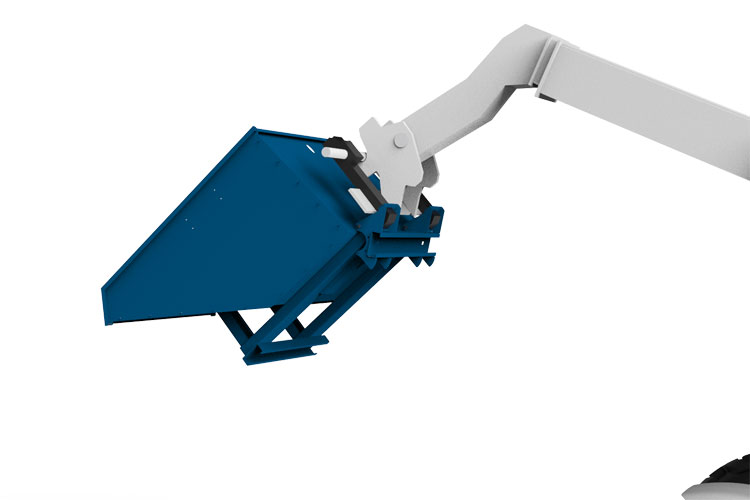

The self-tipping bin is similar to the standard option but features an innovative tipping mechanism, which improves speed, safety and efficiency.

Advantages of the Autolock Tipping Bin

Despite the similarities in appearance, the Autolock Tipping Bin has numerous advantages over the standard option.

No manual control of the bin is required due to the auto tipping mechanism, dramatically improving safety. The tipping bin automatically locks with the forks once it is mounted on the telehandler forklift. It can then be tipped by simply adjusting the angle of the forks from the safety of the cabin, meaning no release level or safety chains are required.

Don’t Just Take Our Word for It!

We challenged the Autolock to a speed test to prove the difference in time, efficiency and safety, compared to a standard forklift.

Main Advantages

1. Speed - driver doesn’t need leave the forklift cabin, increasing the speed of the operations and efficiency of your site operatives.

2. Cost - Autolock is a cost-effective solution allowing for budget savings.

3. Safety – the self-tipping skips presents a big improvement in the safety of on-site personnel as no manual handling of the tipping skip is required.

4. Economical – the automatic tipping mechanism is less weary to both the skip and the telehandler

5. Easy to use and maintain

Autolock Speed Test

What to look out for when buying or hiring a tipping bin?

Ensure you consider how the tipping bin is going to be used. The raked-back design of the Conquip Autolock, for example, prevents damage to the skip increasing its durability.

At Conquip, all our bins are manufactured in the UK, using only high-quality UK, or European steel, ensuring the bin is robust so it can withstand rigorous site conditions. Our weld quality is second to none, with a welding coding standard of BS EN 287-1 and inspections carried out in compliance with BS EN 587-1 – Level B.

Configuration options

The Conquip Autolock can be adjusted to a wheeled tipping bin by the addition of castor wheels, allowing transportation of materials on the solid ground. Four lifting points can also be added enabling the bin to be transported by crane.

The Autolock is easy to transport around site due to the additional fork pockets, allowing the bin to be mounted on the telehandler forks from both sides.

Do you manipulate a variety of materials and you don’t want your bins to get mixed up? No problem! Conquip offers a selection of colour paint options to colour code your tipping bins by the material they transfer.

Tipping bin dimensions

The compact width (maximum of 989mm with castor wheels) of the smallest of our tipping bins – the Autolock 500 – is perfect for house-building as it fits within the standard door frame with the capacity of 500 litres and 1000kg working load limit.

Slightly wider (1224 mm) Autolock 1200 offers capacity of 1200 litres and 2000kg working load limit.

Click the button below for the full specifications and product information.