Off-site construction is here to stay. Previously shamed as “cheap” and “ugly”, modular construction is now properly ‘in play’ across most industry sectors, thanks to cutting on-site labour, reducing costs and increasing efficiency. Sounds good, right?

However, it is not that straightforward. The rise in popularity has presented contractors with a fresh challenge: how do we safely and efficiently lift pods into a building?

In this article, we find out exactly why pods have sky-rocketed in popularity, take a look at the best way to lift pods and delve deeper into the process of installing pods on a construction project.

Demand for bathroom pods has grown substantially in recent years. But why?

Huge rise in pod manufacture, we are curious…

There are many factors that have contributed to this but here are a few we have observed:

- Lack of workforce – Young people are not entering the industry at the same rate as they were 50 years ago, as it is considered an “unattractive” industry. This has led to a lack of both skilled and general labour on sites, meaning processes need to be streamlined. Offsite manufacture is a great example of simplifying and de-skilling the construction process.

- Health and safety awareness – Construction sites are dangerous places. If a contractor can reduce putting people at risk, they will also limit the risk to their staff, minimising costs around training, PPE, and downtime from potential incidents. If the majority of the staff work at an off-site factory, the risks will be greatly reduced and controlled. The only people that need to be at ‘high-risk’ are the small site team responsible for installing the pods and any other work that can’t be achieved off-site.

- Changing attitudes – The industry is having to be more efficient and cost-effective to deliver on issues such as upgrading major infrastructure, the housing shortage, and renewable energy projects.

What are the current trends?

Modular pod installation is more commonly associated in relation to high-rise building construction, but the data shows that off-site methodology is increasingly being used for medium-rise building applications. Most significantly, large retail centre groups who reallocate surplus land to the residential sector for build-to-rent properties. These properties are built with off-site construction planned in during the design phase to achieve higher-quality construction and faster delivery.

So, will the use of prefabricated bathroom pods also pick up traction for low-rise building applications?

Although growth is predicted to be slower, the current trends suggest this could be viable with many major housebuilding companies weighing in on the debate, including Berkeley Group who have invested in a purpose-built, technologically advanced manufacturing facility in Northfleet, Kent. One thing is certain, with such a high demand for prefabricated modular pods – a safe and secure lifting solution is key.

What is the best-practice pod lifting solution?

Selecting the best method for lifting pods depends on a few factors:

01 / Are there lifting points on the pod and are those lifting points LOLER or lift-approved?

02 / Where are the lifting points located and how many lifting points can be used?

03 / The number of pods being lifted.

04 / Whether the pods are all the same or if the weight and size vary between them.

These factors, combined with specific site conditions, will help determine which lifting method is most appropriate. We can offer a variety of lifting equipment solutions to suit your requirements.

CANTIDECK

Our CantiDeck crane loading platforms provide a smooth transition from the floor to the deck. This solution is ideal for applications where multiple pods are required on a single level and where relocation of the deck is infrequent.

Benefits:

- Efficient – High working load limit capacity and easy to relocate.

- Safe – Platforms are secured within the building so load is not suspended.

- Cost-saving – Eliminates complex scaffolding systems.

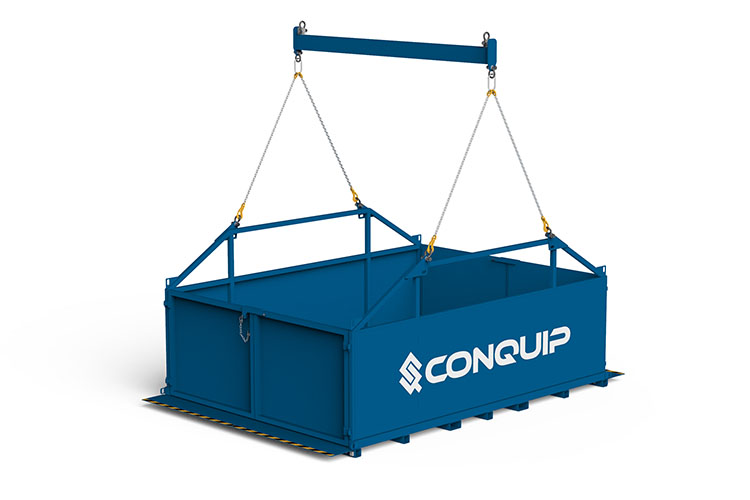

POD LIFTING FRAME

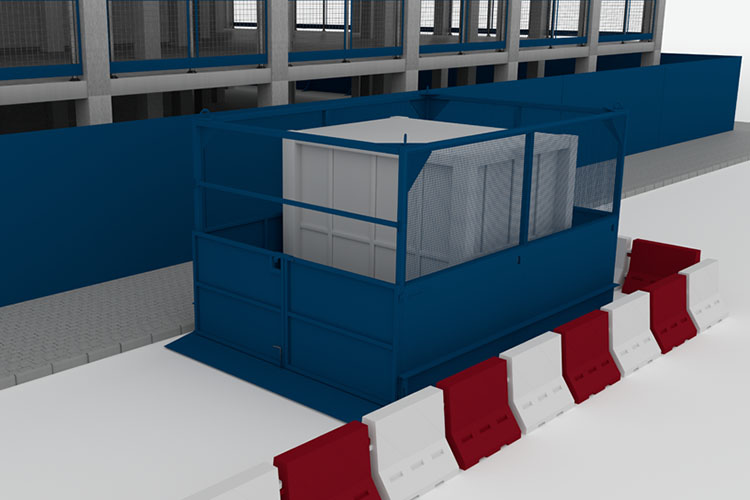

The Conquip Pod Lifting Frame is the popular choice in situations where the use of a CantiDeck is not feasible. The frame can be loaded through the doors on the front, or from above depending on the application and size of the pod.

Benefits:

- Safe – Integrated attachment points on the base and the beams allow the pod to be secured inside the frame and to the building.

- Efficient – Ramp sits on the building slab, allowing easy transfer of pod from frame to building.

- Secure – The doors lock into place for added security and safety.

POD LIFTER

Coming soon – the Pod Lifter. The dynamic design of the latest addition to our range of pod lifting solutions allows for a greater variety of pod sizes. Similar to the Pod Lifting Frame, it can be loaded from the front or above, and uses the same method of installation as the Pod Lifting Frame.

Benefits:

- Versatile – Allows for a variety of pod sizes.

- Safe – Features integrated attachment points on base and beams.

- Efficient – Easily loaded from above or the front.

How do you install a bathroom pod?

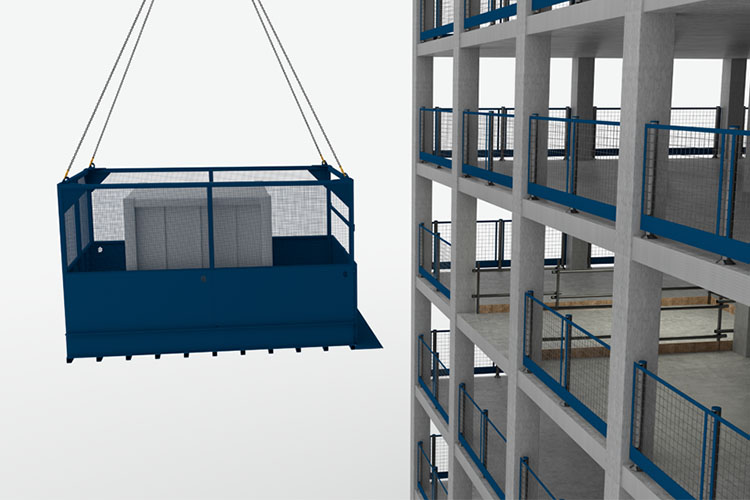

The method of installing bathroom pods will depend on individual site conditions and requirements but below is an overview of pod installation using the Pod Lifting Frame.

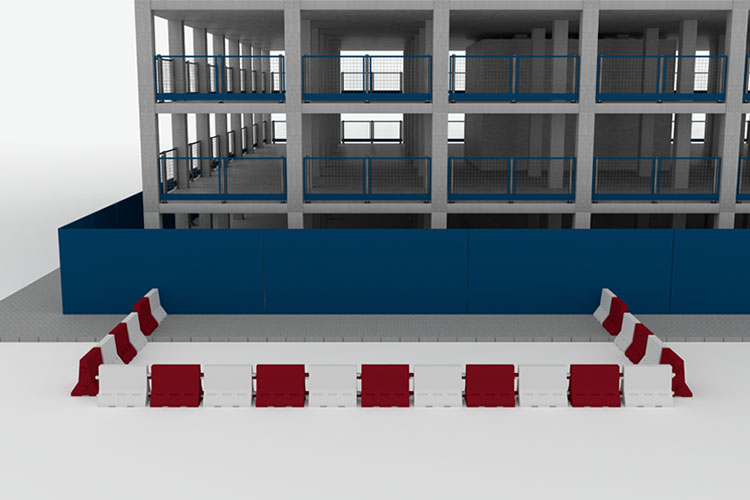

01 / Create an exclusion zone on the ground and in the building.

02 / Load the frame and secure the pod with ratchet straps or similar.

03 / Lift the frame to the desired level and secure to the building.

04 / Ensure the ramp sits level on slab edge.

05 / Transport the pod from the frame into the building.

06 / Unsecure the frame, replace edge protection and lower to the ground exclusion zone.

Need a lifting solution for your next project?

Our large, versatile selection of lifting equipment covers any site requirement. Click the button below to view the full range.

Looking for something bespoke?

We understand that site conditions can present challenges that can demand a different approach from standard-range products. With in-house design and steel fabrication capabilities, we can offer our customers site-specific solutions.

Why not get in touch and speak to our knowledgeable sales team?

References

https://www.unlocking-potential.co.uk/wp-content/uploads/2019/06/Offsite-and-Modular-Building-Market-Research.pdf

https://www.offsitehub.co.uk/industry-news/news/do-it-right-moving-units-correctly/